Marine Alternators

Modern vehicle alternators are made from lighter materials, sized for small batteries and minimal electrical loads and they will not sustain high loads without external airflow for cooling.

Marine alternators, on the other hand, have higher power demands than automobiles to run lights, radio transceivers, navigating equipment, AC/DC inverters, water makers, pumps, winches and other high-amperage devices.

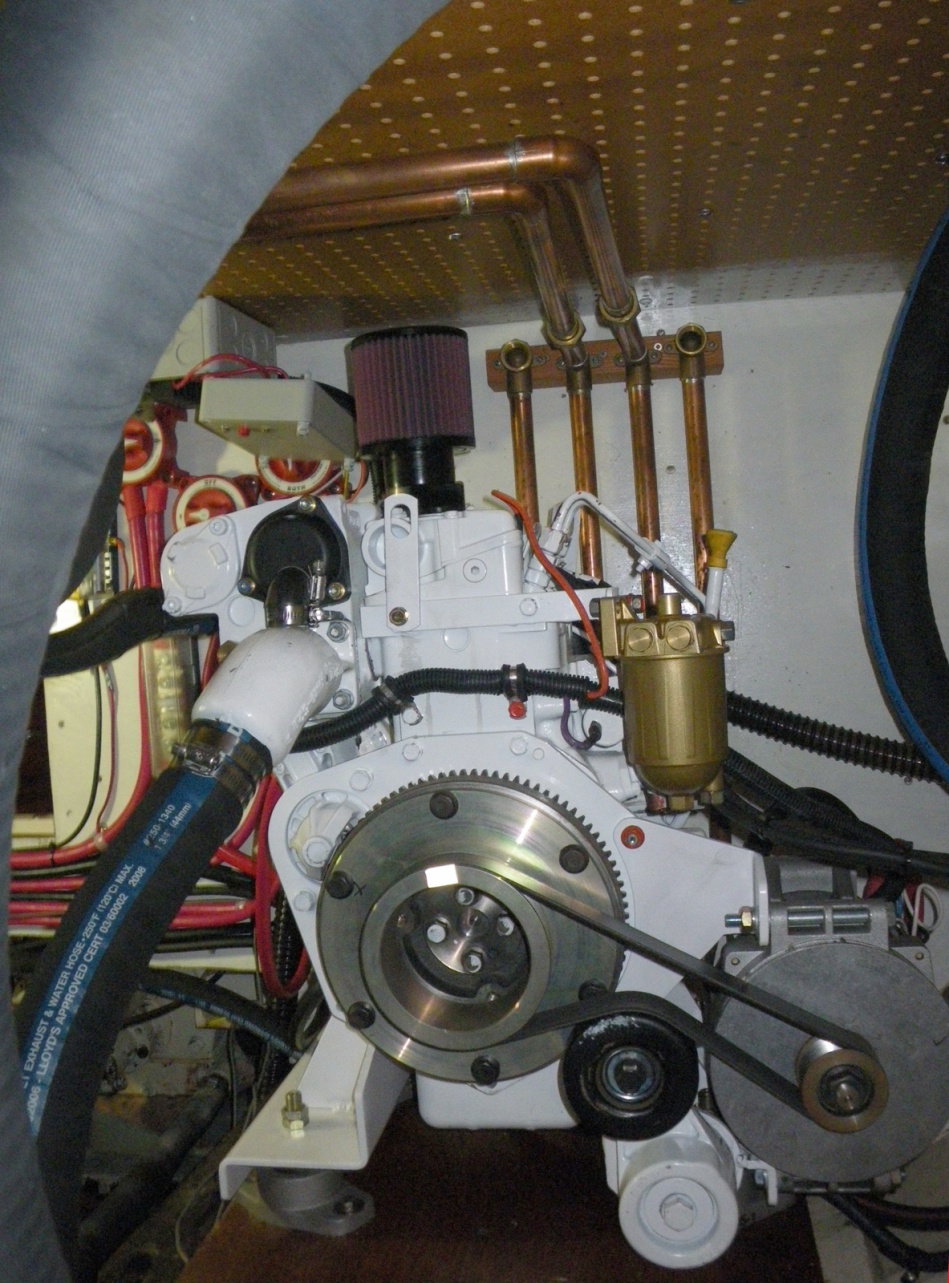

Additionally, marine engines are often installed in enclosed compartments to shelter them from moisture and salt spray. This means that marine alternators must be self-cooling at high loads or have an additional cooling subsystem. Marine alternators must also comply with strict safety specifications not required of cars.

Marine Alternator Features

In order to meet these demands, alternators built for marine use have features not found in automotive-grade units:

- Spark screens that meet Australian standards to eliminate the alternator as an ignition source

- Double-insulation to eliminate electrical shock in wet conditions and prevent sparks

- Dual fans and large heat sinks for self-cooling under high, continuous loads

- Stainless steel bearings, corrosion-resistant metals and heavy-duty coatings

- High output at low RPMs to match marine diesel engine operating conditions

- Battery sensing regulators for high-efficiency battery charging and detection of battery cell failure.

For more information on alternator replacement, servicing or installation or to request a quote please complete our REQUEST FORM. For general inquiries please use our CONTACT FORM.